In the world of machinery and industrial equipment, precision and durability are paramount. To achieve optimal performance and extend the lifespan of machines, engineers and manufacturers rely on specialized lubricants such as way oil. This article will delve into the fascinating world of way oil, exploring its definition, applications, benefits, and how to choose the best one for your needs.

What is Way Oil?

Way oil, also known as slideway oil or machine tool way oil, is a high-quality lubricant specifically formulated for the sliding surfaces of machine tool ways. It possesses unique properties that allow for smooth and controlled movement of machine components, such as guideways, slides, and dovetails. It is typically mineral oil-based and contains additives to enhance its performance and longevity.

The main properties are as follows:

Viscosity

Way oil typically has a higher viscosity compared to other lubricants. This property ensures that the oil forms a strong lubricating film on the sliding surfaces, even under heavy loads. The appropriate viscosity allows for smooth and controlled motion of machine components, reducing friction and wear.

Extreme Pressure (EP) Additives

It is formulated with EP additives to provide enhanced lubrication under extreme pressure conditions. These additives form a protective layer on the metal surfaces, preventing direct contact and reducing the risk of scoring or galling.

Anti-Wear Properties

Way oil contains anti-wear additives that minimize friction between the sliding surfaces and protect against surface damage. These additives create a barrier between the metal parts, reducing the chances of wear, pitting, and scuffing.

Rust and Corrosion Protection

Way oil is designed to protect metal surfaces from rust and corrosion. It contains rust inhibitors that prevent moisture from reaching the metal, thus safeguarding the machinery from oxidation and deterioration.

Demulsibility

Demulsibility refers to the ability of the oil to separate from water or other contaminants. Way oil should have good demulsibility, as it may come into contact with coolant or other fluids in the machining process. Good demulsibility ensures the oil remains effective and doesn’t emulsify, maintaining its lubricating properties.

Thermal Stability

It needs to maintain its properties even under high temperatures. It should have excellent thermal stability, allowing it to resist oxidation and degradation when exposed to elevated operating temperatures. This property ensures the oil’s longevity and maintains its lubricating performance over time.

Adhesion and Tackiness

Way oil should exhibit adhesion and tackiness properties to adhere well to the sliding surfaces. This enables the oil to stay in place and resist being wiped away during high-speed or heavy-load movements. Adhesion and tackiness help provide continuous lubrication and reduce the risk of dry sliding.

Compatibility

It should be compatible with the materials used in the machine’s sliding surfaces. It should not cause any adverse chemical reactions or damage to the components. Compatibility is an essential property to consider to avoid potential issues such as swelling, softening, or deterioration of the machine parts.

By possessing these key properties, way oil ensures efficient lubrication, reduced wear, and improved performance of machinery, contributing to extended equipment life and enhanced precision in machining processes.

Applications in Machine Types

Way oil finds extensive use in various industries, particularly in the manufacturing sector where precision machining is crucial. It is commonly employed in:

Machine Tools

Way oil facilitates precise movement and positioning of machine tool components, ensuring accurate cuts and consistent results.

Industrial Machinery

It is used in heavy-duty equipment such as presses, stamping machines, and injection molding machines to minimize friction and wear.

Slideways and Guides

Way oil lubricates slideways, linear guides, and other sliding surfaces, enabling smooth motion and preventing stick-slip phenomena.

Maintenance and Repair

It can be used to rejuvenate worn-out machine surfaces, reducing play and restoring precision.

Benefits of Using Way Oil

Friction Reduction

Way oil forms a protective film that reduces friction between metal surfaces, preventing excessive heat generation and wear.

Enhanced Precision

By ensuring smooth and controlled movement, way oil contributes to increased accuracy, resulting in improved part quality and tighter tolerances.

Increased Machine Lifespan

Proper lubrication with way oil minimizes wear and tear on machine components, reducing the likelihood of premature failures and extending the equipment’s life.

Rust and Corrosion Protection

Way oil provides a protective barrier against moisture and corrosive agents, guarding the machine’s surfaces from oxidation and rust formation.

Uses in Metalworking

The most common use of way oil in metalworking is for lubricating the slideways and guide systems of machine tools. Machine tools, such as lathes, milling machines, grinders, and machining centers, have precision sliding surfaces and guideways that require smooth and controlled movement.

Way oil is specifically formulated to provide the necessary lubrication to these sliding surfaces, ensuring precise motion and minimizing friction and wear. It creates a protective film between the metal surfaces, reducing heat generation and preventing scoring or galling.

In metalworking applications, way oil enables the following:

Precision Machining

Way oil allows for accurate and consistent cuts, ensuring the desired part dimensions and surface finishes. It helps maintain tight tolerances, critical in industries such as aerospace, automotive, and tool and die manufacturing.

Smooth Sliding

Way oil facilitates smooth and controlled movement of machine components along the slideways or linear guides. This enables operators to position workpieces accurately and execute complex machining operations smoothly.

Reduction of Stick-Slip

Stick-slip, also known as “stiction,” refers to the jerky or uneven movement of machine components due to high friction. Way oil’s lubricating properties minimize stick-slip phenomena, ensuring smooth and continuous motion, leading to improved machining results.

Longevity of Machinery

Proper lubrication extends the lifespan of machine tools by reducing wear on critical components. It helps prevent premature failure and the need for costly repairs or replacements, thereby enhancing productivity and cost-effectiveness.

Maintenance and Reconditioning

Way oil can also be used for maintenance and reconditioning purposes. If slideways or guides become worn or develop play over time, applying it can help restore precision by minimizing the looseness and ensuring smoother operation.

Overall, way oil is indispensable in metalworking applications, providing essential lubrication to machine tool slideways, guideways, and other sliding surfaces. Its use ensures precise, efficient, and reliable machining operations, ultimately contributing to improved productivity and the production of high-quality metal components.

Choosing the Best Product

Selecting the right product for your machinery requires careful consideration. Here are some factors to keep in mind:

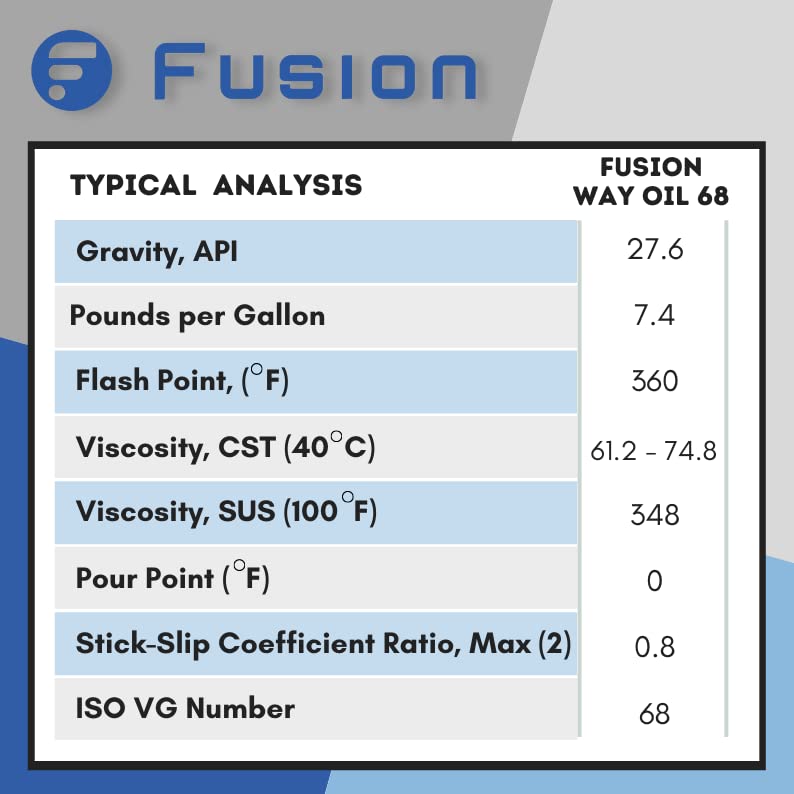

Viscosity

Choose a product with a viscosity appropriate for your machine’s operating conditions and load requirements. Consult the manufacturer’s guidelines or seek expert advice if necessary.

Additives

Look for products that contain additives designed to enhance performance, such as anti-wear additives, rust inhibitors, and extreme pressure (EP) additives.

Compatibility

Ensure the product is compatible with the materials used in your machine’s sliding surfaces. Certain additives or base oils may not be suitable for specific materials, potentially leading to accelerated wear.

Quality and Brand

Opt for reputable brands that adhere to industry standards and have a track record of producing reliable lubricants. Check for certifications or approvals to ensure the quality of the product. Fusion is proud to produce American-made and environmentally-friendly products you can rely on for a consistent quality.

Maintenance Practices

Establish a regular maintenance schedule, including oil analysis and oil change intervals, to ensure the product performs optimally and protect your machinery investment.

Conclusion

Way oil plays a crucial role in maintaining precision, minimizing wear, and extending the life of machinery. By choosing the right product and implementing proper lubrication practices, manufacturers and engineers can enhance performance, improve part quality, and reduce maintenance costs. So, embrace its power and unlock the full potential of your machines while enjoying the benefits of prolonged reliability and efficiency.